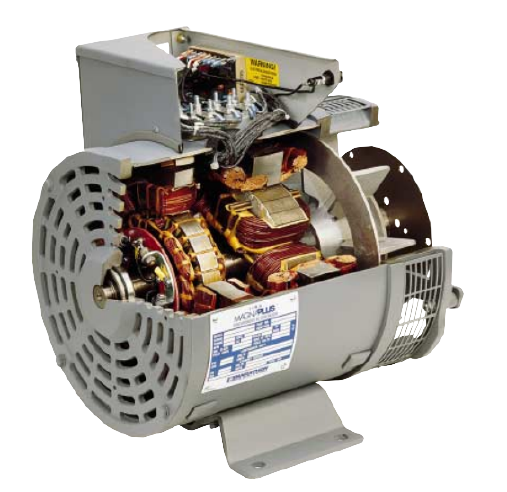

MARATHON MAGNAPLUS GENERATOR END 190 TO 375 KW OUTPUT

MARATHON MAGNAPLUS GENERATOR END

MODEL: 433PSL6216

CONTINOUS DUTY OUTPUT

190 KW AT 120/240 VOLTS SINGLE PHASE

343 KW AT 120/208 VOLTS THREE PHASE

375 KW AT 277/480 VOLT THREE PHASE

AVAILABLE WITH SAE STANDARD ENGINE ADAPTION

SHIPS WITH SE-350A VOLTAGE REGULATOR

FREE SHIPPING WITHIN THE CONTINENTAL UNITED STATES

FEATURES

ALL THREE-PHASE GENERATOR ENDS ARE 12-LEAD RECONNECTABLE, providing voltage and phase flexibility. More than 20 stock models ranging from 5–430 kW (60 Hz) and 5–425 kVA(50 Hz).

DEDICATED SINGLE PHASE MODELS, offer a price advantage with units in stock ranging from 4 to 155 KW

EASY MOUNT SAE ADAPTERS are provided with every generator to simplify coupling to the prime mover. Generator foot mounting dimensions are not affected by adapter choice. Special adapters can be ordered for any automotive engine as well.

TWO BEARING MODELS ARE AVAILABLE AT NO EXTRA COST, with standardized shaft sizes to match commercially available pulleys

THE SE350 VOLTAGE REGULATOR, provides 1% voltage regulation and offers commercial features such as under speed protection and stability adjustment.

OPTIMIZED ELECTRICAL DESIGN, with four-pole, brushless windings, utilizing a 2/3 pitch design to minimize harmonic distortion. The main rotor, utilizing Marathon Electric’s unirotor construction, provides exceptional wave shape and voltage balance. The unirotor construction method incorporates full amortisseur windings facilitating parallel operation and distorting loads.

Enhanced Ventilation, created by a high efficiency cast aluminum fan and optimized internal air flow patterns, maximizes heat transfer and minimizes hot spot differentials for extended winding life. Durable aluminum alloy fans avoid breakage problems associated with welded steel or plastic fans.

Fully Guarded for operator safety and generator protection. No rotating or electrically energized parts are exposed. All openings are covered by louvers or screens.

Heavy Duty Bearings are double shielded and pre-lubricated for the life of the bearing. This helps resist contamination and ensures a minimum B-10 life of 100,000 hours.

Class H Insulation System, utilizes an unsaturated polyester varnish for optimal insulation life and superior moisture protection. A tropical insulation is added for increased environmental protection. Field windings are wet wound with epoxy and designed to withstand over speeds of 125%. All windings are100% copper with class H insulation.

Design Specs and Agency Approvals. All MAGNAPLUS® units meet NEMA MG1-22, BS5000, CSA C22.2 and IEC 34-1 requirements.

MARATHON FULL LINE CATALOG (12 MB KB)

MAGNAPLUS BROCHURE (297 KB)

MAGNAPLUS OPERATION AND INSTALLATION MANUAL (318 KB)

MAGNAPLUS ENGINE AND FLYWHEEL ADAPTER CROSS REFERENCE (9 KB)

12 LEAD GENERATOR CONNECTION DIAGRAM (51 KB)

MAGNAPLUS DIMENSIONS (51 KB)

SAE ENGINE ADAPTER AND FLYWHEEL COUPLER MEASUREMENT GUIDE (162 KB)